Understanding the Importance of Substrate Preparation

Substrate preparation serves as the cornerstone of achieving a flawless, enduring finish. This preparatory phase is crucial as it directly influences the adhesion, durability, and overall quality of the coating applied. Substrate preparation involves a series of meticulous steps designed to ready the surface for coating application, thereby enhancing its performance and longevity.

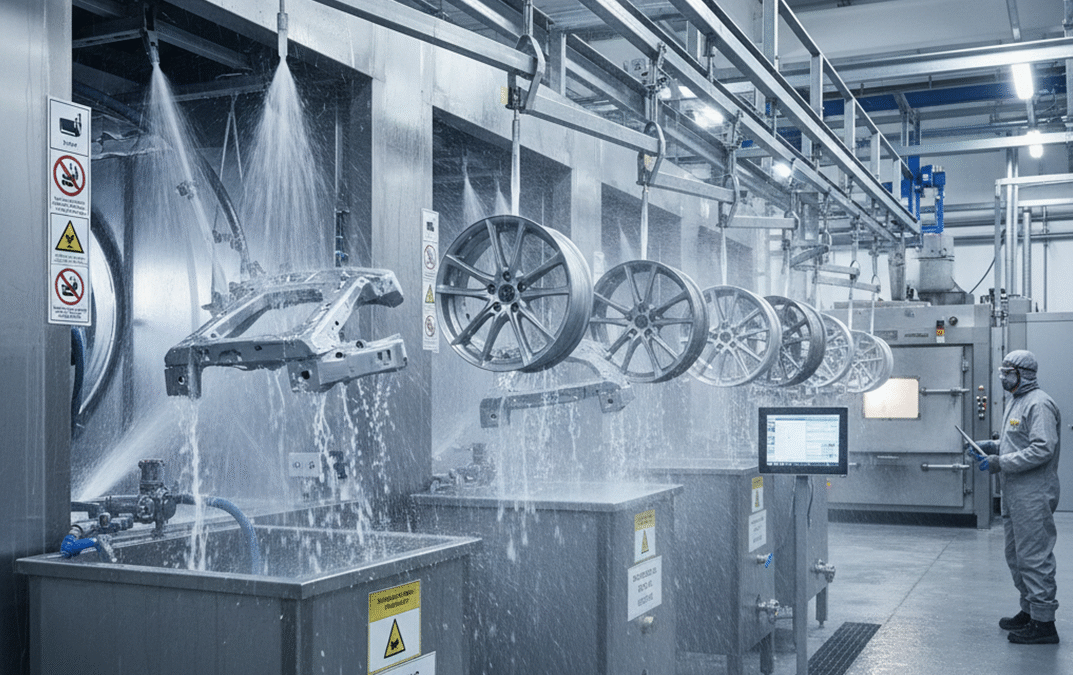

Primarily, the process begins with cleaning the surface to remove contaminants such as dust, oil, grease, and rust. These impurities can impede the adhesion of the coating, leading to premature failure. Therefore, thorough cleaning is imperative to ensure that the coating bonds effectively with the substrate.

Following cleaning, surface conditioning is often employed to modify the physical or chemical properties of the substrate. Techniques like sandblasting or chemical etching may be used to create a surface profile that promotes optimal adhesion. This step is vital for achieving a uniform finish and preventing defects such as peeling or blistering.

By prioritizing substrate preparation, manufacturers not only enhance the aesthetic appeal of metal components but also ensure their resilience against environmental stressors. Such meticulous groundwork sets the stage for a successful coating application, ultimately extending the life and performance of the coated item.

Different Types of Metal Substrates and Their Characteristics

In the realm of powder coating, understanding the distinct characteristics of various metal substrates is crucial for achieving optimal results. Each metal type possesses unique properties that influence how it interacts with coatings, thus affecting the durability, appearance, and performance of the finished product. Here, we explore the most commonly used metal substrates in industrial applications and highlight their defining features.

Steel

Steel is a highly favored substrate due to its strength and affordability. It is often used in construction and manufacturing. However, steel is prone to corrosion, necessitating a thorough pretreatment process to ensure long-lasting adhesion. Common treatments include sandblasting and applying anti-corrosive primers.

Aluminum

Aluminum, known for its lightweight nature and resistance to rust, is frequently used in automotive and aerospace industries. Its non-ferrous nature means it corrodes less than steel, but it can still oxidize. Thus, it often requires surface preparation to remove oxide layers and enhance coating adherence.

Galvanized Steel

Galvanized steel offers an additional layer of protection against corrosion due to its zinc coating. This makes it ideal for outdoor applications. However, the zinc layer can present challenges for coating adhesion, often requiring specific pretreatment to ensure the powder coating adheres properly.

Understanding these characteristics enables professionals to select appropriate pretreatment and coating processes, ultimately enhancing the longevity and aesthetics of the finished product. By tailoring the approach to the specific substrate, one can achieve superior results that meet both functional and aesthetic requirements.

Essential Pretreatment Techniques for Metal Substrates

In the realm of powder coating, the significance of proper substrate preparation cannot be overstated. Pretreatment is an indispensable step that ensures the longevity and efficacy of the final coating, acting as the foundation upon which the powder adheres. Without this crucial stage, even the most advanced powder coatings may fail to deliver their full potential in terms of durability and aesthetics.

Cleaning the Surface

The first and foremost step in substrate preparation involves meticulous cleaning to eliminate all forms of contaminants such as dirt, grease, and oil. These impurities can significantly hinder the adhesion of the powder coating, leading to imperfections and premature failure. Common cleaning techniques include degreasing using solvents or alkaline solutions.

Surface Conditioning

Once cleaned, the metal surface should be conditioned to improve adhesion. This often involves mechanical abrasion techniques such as sandblasting or chemical treatments like acid etching. These methods serve to roughen the surface, creating a profile that enhances the mechanical bond between the substrate and the coating.

Applying Conversion Coatings

Lastly, a conversion coating may be applied to further promote adhesion and provide additional corrosion resistance. Phosphate and chromate coatings are popular choices, offering a chemical layer that enhances the substrate’s receptivity to the powder coating process.

By integrating these pretreatment techniques, businesses can ensure their powder-coated products achieve optimal performance and aesthetic appeal, maximizing the benefits of powder coating technology.